Established in 1995 and headquartered in Yandian Town, Linqing City, Liaocheng, Shandong Province—a pivotal hub of China’s bearing industry—Liaocheng Libest bearings Technology Co. Ltd. has evolved over nearly three decades into a modern, integrated enterprise specializing in the R&D, production, and sales of high-precision, high-reliability bearings. With a workforce of 120 employees and a sprawling production facility spanning 150,000 square meters, the company operates advanced intelligent production lines and cutting-edge testing equipment. Its core products, including tapered roller bearings and thrust bearings, are widely applied in automotive manufacturing, construction machinery, mining equipment, and precision instruments. Renowned for exceptional quality and service, the company not only dominates domestic markets but also exports to over 20 countries and regions across the Middle East, South America, and Southeast Asia, solidifying its position as a key global player in the bearing industry.

In its early years, the company focused on domestic demand, introducing advanced bearing manufacturing equipment and establishing a preliminary quality management system. Specializing in tapered roller bearings, it quickly gained recognition in North China through stringent production standards and customer-centric service.

To meet growing market demands, the company expanded its facility to 100,000 square meters, integrating automated grinding lines and heat treatment equipment. It obtained ISO9001 certification and diversified its product range to include thrust bearings and non-standard bearings, marking its initial foray into international markets with successful entry into the Middle East.

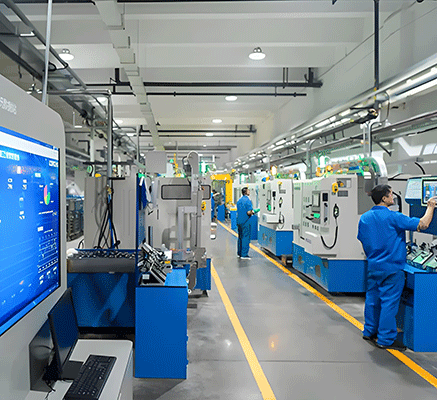

Embracing intelligent manufacturing, the company adopted ERP systems and AI-powered visual inspection technology to digitize production processes. A dedicated international trade team was formed, driving partnerships in South America and Southeast Asia, with export revenue growing at an annual rate of over 30%. In 2022, the completion of Phase II factory construction expanded total floor space to 150,000 square meters, boosting annual capacity to 5 million units and positioning the company among China’s top-tier bearing manufacturers.

The company’s innovation-driven product portfolio addresses diverse industrial needs:

Manufactured from premium alloy steel and precision-ground, these bearings feature high radial/axial load capacity, low friction, and extended durability. With P5-grade accuracy, they are ideal for heavy-duty trucks, construction machinery transmissions, and mining equipment, even in extreme conditions such as high temperature and humidity.

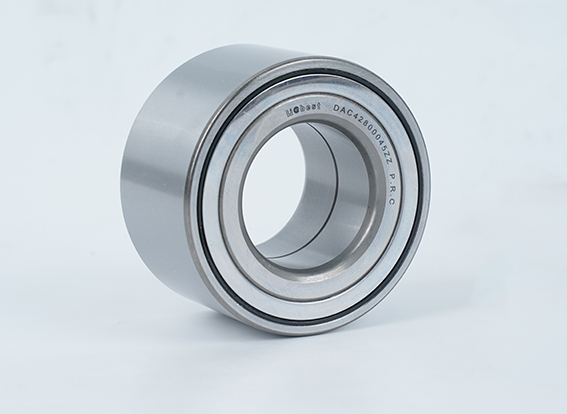

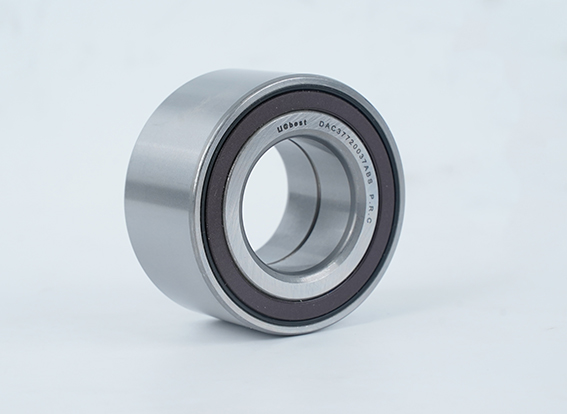

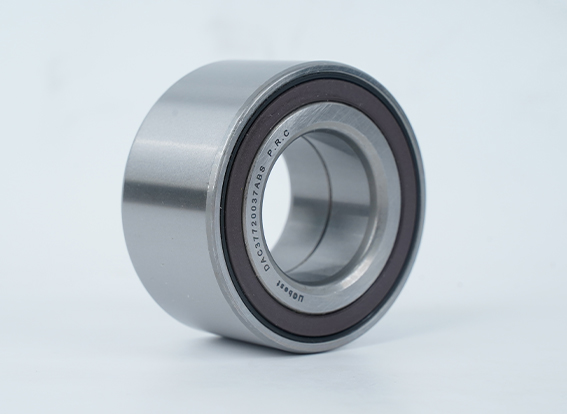

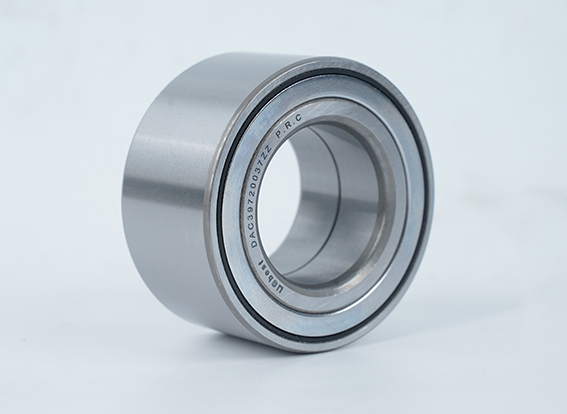

Focusing on wheel hub bearing series, it integrates core categories such as double-row angular contact ball bearing and tapered roller bearing, adopts innovative sealing structure and reinforced raceway design, and effectively reduces running noise and friction loss through accurate control of clearance and surface hardening treatment process, so as to ensure that the vehicle can still maintain excellent reliability and durability under high-speed driving, frequent braking and complex road conditions. The product is widely applicable to new energy vehicles, heavy trucks, engineering machinery equipment and other scenes, providing high-precision and long-life professional solutions for the wheel end system.

Leveraging robust R&D capabilities, the company provides non-standard bearing design, material optimization, and failure analysis services. Notably, it developed lightweight bearings for leading automotive manufacturers to support energy efficiency and emission reduction goals.

Domestically, the company has built a service network covering 30 provinces, establishing long-term strategic partnerships with major Chinese enterprises. Internationally, while deepening its presence in the Middle East and Africa, it has expanded into South American markets like Brazil and Chile under the Belt and Road Initiative. By 2023, overseas sales accounted for 45% of total revenue, cementing its role as a core supplier of industrial bearings in the Middle East.

The company prioritizes intelligent and eco-friendly production: Smart Production: Plans to introduce German CNC machines, Japanese superfinishing equipment, and fully automated assembly lines within 3-5 years, achieving end-to-end automation from raw material processing to final packaging.

Quality Assurance: Equipped with coordinate measuring machines, spectrometers, and fatigue testers, all products undergo 12 critical inspections to ensure 100% compliance.

Green Initiatives: Utilizing waste heat recovery systems and water-based coolants, the company has reduced energy consumption per unit by 25%.

The company allocates 9% of annual revenue to R&D, focusing on enhancing product quality, optimizing production processes, and reducing bearing noise.

Guided by the philosophy of “Bearing Heavy Loads, Carrying Greater Responsibilities,” the company: Employee Welfare: Offers skill training, equity incentive programs, and comprehensive health checkups, maintaining an employee turnover rate below industry averages for five consecutive years.

Community Support: Has donated over RMB 2 million to local schools and established the “LIBEST Scholarship” to support education in Yandian Town.

Aiming to become a global leader in high-end bearings, LIBEST BEARING will focus on emerging sectors such as new energy vehicle bearings and smart sensor-integrated bearings. Plans include a RMB 120 million investment in a digital factory and collaboration with European partners to develop magnetic levitation bearing technology. By 2028, the company targets a presence in 50 countries, driving global industrial advancement through the power of Chinese innovation.

Powerengine bearing, nearly 30 years of originality, intelligent manufacturing and accurate future, driving the world forward.